Điều chia sẻ

EXPENSIVE OR AFFORDABLE? – Uniform T-Shirts

Price is always a top concern for everyone before making a decision to purchase any product or service. To determine whether a product is expensive or cheap, we need to consider multiple factors before making a judgment. A wrong assessment can lead to serious consequences related to finances, product quality, or user experience—especially when it comes to corporate purchases.

This article will cover the key components that make up the cost of a uniform t-shirt. Once you understand them, you’ll have a clearer foundation for evaluating whether a shirt is "expensive or affordable," and make more informed purchasing decisions.

1. Fabric Type

100% Cotton: Soft, breathable, and more expensive.

Cotton 65/35 (CVC), TC: Blended with polyester, less wrinkling, medium price.

Polyester (PE): Inexpensive, less breathable, often used for budget shirts.

If a salesperson only says “cotton,” it means they may either lack knowledge or are being vague intentionally. Most consumers just want to hear the word "cotton," but the real question is: What percentage of cotton is it? Some also try to impress you by saying it's "4-way stretch fabric," which is more of a marketing term.

When discussing fabric costs, the core determinant of price is the material itself. Terms like "plain fabric" or "pique (lacoste)" refer only to the weaving technique. Mentions of 2-way or 4-way stretch refer to the added elasticity.

If the consultant doesn’t clearly explain the main influencing factor, there’s likely something fishy going on—and you should proceed carefully.

=è> Conclusion: The fabric type determines most of the durability, comfort, and cost of a t-shirt.

2. Design and Sewing Quality

T-shirt styles include crew neck, polo collar, short sleeves, long sleeves, slim fit, relaxed fit, etc. The more design elements such as sleeve cuffs, side vents, color panels, or piping, the higher the price.

The simpler the shirt, the quicker and easier it is to produce, requiring fewer skills and less specialized equipment. On the other hand, shirts with complex details require skilled labor, longer time, and more machinery—raising the cost.

Even seemingly minor details—like using double stitching (Kansai machine), hidden seams, or fine finishing—can significantly affect pricing.

3. Printing / Embroidery

Screen printing: Cost-effective for large orders.

Decal/heat transfer printing: Suitable for small quantities and detailed designs.

Direct-to-garment (DTG): High-quality, full-color printing, but expensive.

Embroidery: Durable and elegant, but more costly than printing.

A uniform t-shirt with just a small 1-color logo (like the Nike swoosh) is simpler and quicker to design and print/embroider. However, placing designs on different areas—left chest, right chest, sleeves, back, waist—adds to complexity and cost.

Each material and design requires an appropriate printing method. Not all techniques work with all fabrics or colors. Even choosing between printing and embroidery requires expertise—not all sizes and positions are suitable for both.

=è> The placement, number, and size of prints/embroideries directly affect pricing.

4. Order Quantity

The more you order, the lower the unit price—thanks to economies of scale in labor, material, and production setup.

This is why many suppliers have a MOQ (Minimum Order Quantity). Not every factory accepts orders of 1–3 shirts. Remember the old saying: “Customer is king”? Well, even kings have limits. Businesses that accept any quantity, even one shirt, are extremely rare—and precious.

It’s unrealistic to expect the same level of attention for a 3-shirt order compared to one with thousands. And if someone offers too-good-to-be-true prices for micro-orders, you should proceed with caution.

==è> Don’t expect the same unit price for low-volume orders. Consider your role—are you a regular customer or a VIP bulk buyer? It’s so hard to get profit, that’s why a few or nobody accepts your order. Let think about that.

5. Delivery Time

Urgent orders may incur rush fees or overtime charges.

If your project is on a tight schedule, yet still requires good quality and specific requirements, you should be ready to pay more.

Rushed orders face the risk of:

Fewer suppliers willing to accept

Delays or missed deadlines

Compromised quality

Higher prices

==è> Tip: Try to plan ahead to avoid these challenges.

6. Additional Accessories

Custom woven labels, hangtags, individual packaging, boxes, zip bags, and custom-printed paper bags all increase costs.

This is straightforward: the more extras you want, the more you’ll pay.

7. Shipping Costs

This depends on delivery location—sometimes included, sometimes separate.

For international shipments (e.g., to the US) or special delivery methods, additional fees will apply.

8. Brand Reputation and Service

Well-known, experienced suppliers usually charge a bit more—but they offer:

Better quality

On-time delivery

Expert consultation

Warranties for defects

Delivery deadlines can be a major stress point. Every supplier will confidently tell you:

“Don’t worry, we’ll deliver on time.”

But only experience will tell whether they keep that promise.

==è> Final Thoughts

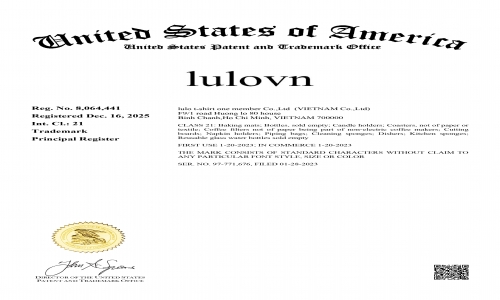

Let me share a helpful tip: Lulo Uniform T-Shirts accepts orders starting from just 1 shirt. As mentioned above, this is rare—but yes, it exists!

With Lulo, once your order is placed, you can truly rest easy. They’re known for:

Timely delivery

Fair pricing

High-quality products

That’s why Lulo has thrived for over 13 years.

Need custom shirts? Add Zalo 0909 506 533 today, and don’t forget to share this info with your friends or colleagues who need uniforms.

Wishing you a great day!

Bài viết khác